Recently I decided it might be fun to see what VR was about. I’ve never been a gamer and I didn’t want to waste a lot of time, but I did want to get a good feel for where the current state of VR simulations are. I think you have to own a system to have adequate time to get a feel for it.

My expectations were initially a bit low. I had read about the screen door effect, god rays, and complaints about resolution, field of view etc.. However I was surprised at how well Gen 1 headsets work. Yes, I can see the pixels, but it is immersive and you tend to forget about the pixels pretty quickly and just react to your virtual environment.

VR Hardware:

I started with an Oculus Rift system with 2 front firing and 1 rear firing sensor. The Oculus Touch controllers are excellent and with 3 sensors the head tracking and Touch tracking are excellent. The Rift is also relatively light compared to most and has pretty good quality headphones built in. I mounted the sensors on tripods in my media room.

There are many headsets available including the Vive, recently released Windows MR headsets such as the Samsung Odyssey, and kick starter headsets like the Pimax. I picked the Rift because a number of the simulation titles are optimized for Oculus and it’s low price of $350. VR headsets are in their infancy and will evolve very quickly so I consider them somewhat disposable like early digital camera bodies, and I don’t want to debate which is best because something much better will make them all obsolete quickly.

VR software support:

- SteamVR – supports everything

- Oculus – supports only Oculus

- ReVive (takes Oculus only titles and allows Vive / Windows MR headsets to work with a slight speed penalty)

Titles written specifically for SteamVR seem to work uniformly well on everything. This is a great standard that the Vive/Oculus and Windows MR headsets can use.

Titles with direct Oculus support will run faster on the Rift. Many of the car racing games have direct Oculus support and SteamVR support.

ReVive involves an overhead process to make other headsets talk to Oculus only titles.

Purchasing VR titles:

Generally you will want to purchase your VR titles through Steam since they will work with anything. If you purchase through the Oculus store the VR titles will only work with Oculus devices.

Computer Hardware:

i5-4690K, 16Gb, 250Gb & 1Tb SSD’s, GTX Titan

Windows 10 Professional

This is a small mini-ATX computer I put together for my RC Helicopter flight simulator a while back and it’s doing a pretty good job with gen 1 VR, but I don’t have all the settings cranked up. Likely the whole system will need replacing for the next generation of VR headsets. Obviously there are much more powerful systems out there and a GTX 1080TI or upcoming Volta card would certainly be much more powerful.

My Oculus Rift headset and 3 sensors use all 4 of the USB 3.0 ports on this computer and the HDMI graphics card port. I’m running a DVI port to the TV on the wall. One front USB 2.0 port supports both the wireless mouse and keyboard. That leaves 3 more USB ports. Only 1 of the front ports is needed for my car racing rig because it is an integrated ecosystem that all plugs together. My flight rig uses all of the remaining 3 USB ports.

A few things about VR:

VR Nausea: There are two things that can cause nausea in VR.

- If the computer is unable to generate a solid frame rate of 90fps the head tracking may stutter or lag and cause queasiness.

- The other bigger issue is when you see yourself moving in VR but can not feel the accelerative forces on your body.

There is a rating system for VR titles based on how much motion there is.

- Comfortable

- Moderate

- Intense

An example of a Comfortable title is Oculus’s Robo Recall which is a lot of fun. It works best in room scale and you are swinging around shooting and grabbing derelict robots. There is lots of action, however you teleport from place to place and never experience motion.

A Moderate title would be Mission ISS or Lucky’s Tale. In Mission ISS you can grab handles and move around in a weightless environment. In Lucky’s Tale you move like a balloon tethered to the main character that you control like a character in Mario Brothers.

The car racing and flight sims are Intense. There is lots of motion happening in VR that you don’t feel in real life and for some people that causes queasiness. My son had no issues. However I can remember the first time I slid off the road in Dirt Rally and threw my car in reverse. My stomach did flip flops as the car flew backwards and I felt nothing. FWIW I think car track racing games are much easier on your stomach than titles like Dirt Rally ( which is my favorite VR title )

I have one other title that is rated Intense for a reason other than motion. It’s called “The Climb” and it’s rated Intense because of the potential for vertigo while you are climbing a cliff face with your bare hands hanging hundreds of feet off the ground.

The good news is that after about a week or so I got used to this and it was no longer an issue. Until then I found ginger pills taken with food 30-60min before playing helped me get through half an hour or so of game play. Now I can play for over an hour with no ill effects.

My Car and Flight Rigs:

I found out very quickly that like anything else you can spend an unlimited amount of money on these rigs and they can get very heavy and bulky fast.

My constraints were:

- Space – I wanted something I could foldup/break down and stow in the closet.

- Quality – I wanted something very good so I didn’t have regrets or feel like I missed out on the experience, but with a solid following and strong resale value when I was done.

Shared Seat:

I ended up with a 2008 Volkswagen Passat fully manual passenger seat from a local junk yard for $40. Passenger seats tend to have less wear. It slides front/back, reclines, has lumbar support and the seat bottom lifts up to become more upright which works well for flight sims and then drops down which is better for the car sims. I took it home, pressure washed it, used my shampooer to pull most of the water out. It cleaned up nicely.

I just had to build a basic support for the rails with a cross member that I could use to secure it to the two rigs.

Down for car racing (left) , Up for the flight rig (right)

Building a Car Racing Rig:

To gain portability the chair detaches from the controls and the controls collapse down. I went with a Wheelstand Pro 2 and RGF attachment to hold the shifter. It was never designed to support a hand brake which I could easily pull forward, but a ratcheting strap took care of that issue.

Granted an 80/20 frame or something like an RSeat RS1 would be more rigid, but in VR, I’ve not noticed any issues. The critical thing is that I can get on the brake hard and I can pull back hard on the hand brake.

The controls are all Fanatec ClubSport equipment.

- Clubsport 2.5 Wheelbase

- Porsche 918 racing wheel

- Clubsport 3.0 pedals & Performance Brake kit

- Clubsport 1.5 shifter

- Hand brake

Immersion and Vibrations:

The Clubsport 2.5 Wheelbase has two strong motors that pull in opposite directions. They produce something called Force Feedback. It adds resistance and pulls the wheel in directions based on the physics of the car. It also lets you feel bumps and the sensation of loosing traction as it goes light or goes airborne. These pedals also have a small shaker in the brake and gas pedal to simulate ABS kicking on.

A nice feature that most of the car racing software have is sharing information that can be accessed by 3rd party software. This includes information about the road surface like it’s texture, bumps and also engine rpm, speed, when the rear wheels are sliding etc. This is great for aftermarket HUD’s and is what SimVibe relies on.

In the system I’ve put together there is a transducer mounted to the bottom of the seat, the pedals and the gear shift. This adds bumps, impacts, engine vibration the feeling of your rear wheels sliding with many effects available.

I’ve found that the steering wheel force feedback and additional vibrations make driving in VR feel much more realistic and add to the experience.

To make SimVibe work with my setup involved the following:

1. Installing the SimVibe software and allowing it to find the software I have installed so it could setup profiles.

2. Modifying the profiles to taste. They can be done by title and even by specific car in each title.

3. I’m using 2 x 1.8” stereo to RCA plugs from the computer to an old AV receiver to drive 3 transducers.

From my experience having vibrations in the seat of your pants matters most followed by the pedals. The gear shift having engine vibrations adds but not nearly as much.

The end result is very impressive and feels believable. I could play for half an hour and work up a bit of a sweat pulling against the wheel and driving.

Flight Rig:

For flying I’m currently only using DCS World which is downloadable with a couple aircraft on Steam for free. However I also got their Huey, A-10, F-15, and P-51.

The HOTAS is the Thrustmaster A-10 stick and throttle.

The pedals are MFG Crosswinds from Croatia. I also ordered a 3” extension pipe for the stick from MFG when I ordered the pedals. The extension really helps.

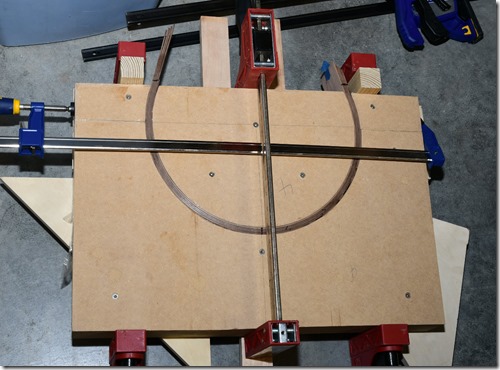

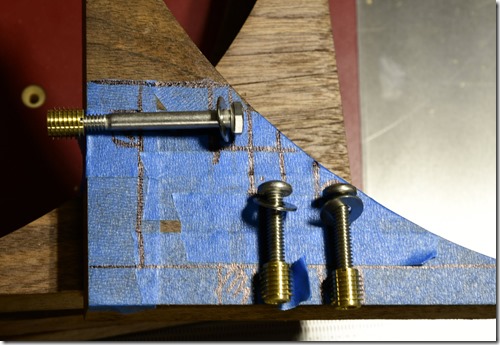

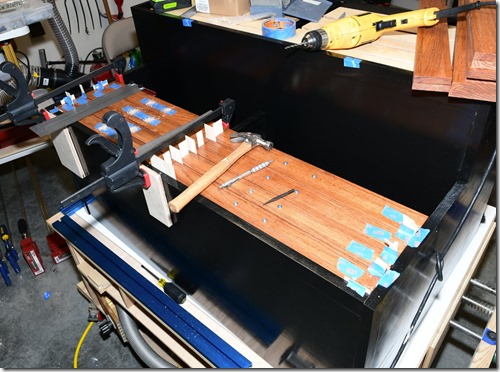

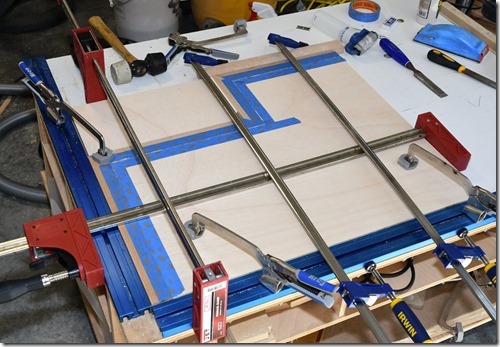

There is a lot more plywood work on this. Basically the seat is slid until the foot pedals feel right, then the stick is slid up to the front of the seat and the throttle is slid to a comfortable position.

My flight rig does support vibrations in the seat through a different software package. You can feel rumble on the runway, various vibrations, projectiles firing etc..

Car Racing vs. Flight vs. Other VR

This is a very personal thing. There are arcade experiences as well as realistic simulations available for both.

If I have a friend over, the car racing sim is much easier to get going quickly since most people know how to drive. The flight simulations can be very involved and there are lots of switches to map and training involved before a person can dive in.

For some aircraft you can spend hours just learning all the controls, how to do a preflight, starting the engines up and taxi out to the runway and take off. It can also take a while to learn how to land and use all the weapons.

Car racing on a track frequently involves shaving fractions of a second off times. If you want a realistic racing experience iRacing has races that kick off every hour and that try to bin real people by ability level. There is no AI, and they use the full rules of racing. Others like Assetto Corsa and Project Cars have AI drivers allowing racing without Internet access, but also have online multiplayer racing. However they allow doing things like turning off damage and making things easier for the racers and can allow a group of friends to start up a race by invitation only.

There are lots of ways to enjoy these simulations and I would argue that VR is much more immersive when you have a complete set of REAL controls at your finger tips. I felt like I was flying a Huey helicopter and it is an interesting experience.

In real life I have Autocrossed, done a Rally, and had flight instruction in a Cessna 152 and a couple sailplanes.

Real life experiences are fantastic, but I will never drive an ultra expensive Rally Car around hairpin turns on cliffs in Greece, or go airborne over sharp hills in Finland. Real life for those experiences is simply too dangerous and expensive for me to do in real life. I’ll never fly an F-15 or P-51, etc.. or “free solo” climb up a rock face. VR allows me to get a “taste” of what doing some things is really like and that is where I think VR shines.

I’m still not a gamer and I enjoyed building my rigs and figuring out how to make everything work more than playing VR games. However I have enjoyed the VR experience and I’m very sure that the software titles will become more and more compelling over time and the immersion more and more realistic.

I’m very excited about where Augmented Reality is going and I can see some serious real world uses for that well past games. VR can already be used as a training tool, but I see AR as potentially being a new level of day to day existence.

Update: 1/23/2018 I’ve been playing Eve Valkyrie Warzone with my Flight controls for a few weeks. This is a childhood fantasy realized. It feels like I’m piloting a space fighter launched Battlestar Galactica style from a space carrier with a team of real and AI players pitted against a team of real and AI players. I’ve gotten more grins from this game than anything I’ve experienced to date. The production values of this game are excellent. The sights and sounds are perfect. As you progress your rating increases and you are grouped with a team and opponents at a similar level. As you level up and get better so does your competition. As a result the game changes over time keeping things interesting.